One of the assets Xeamos brings to the table for yacht builders is our ability to cover the complete scope of an emissions-reducing solution, from engine outlet to hull penetrations. That was the case with an 85-metre motor yacht from a renowned yard in a recent project that also involved close cooperation with our Dutch colleagues from MarQuip.

The original brief called for meeting emission limits, ensuring low noise levels and designing a system that would fit in an engine room where real estate was at a premium. As the engine has a specific minimum and maximum backpressure demand depending on rpm, a backpressure-regulating valve also need to be added to the design.

Bespoke solutions

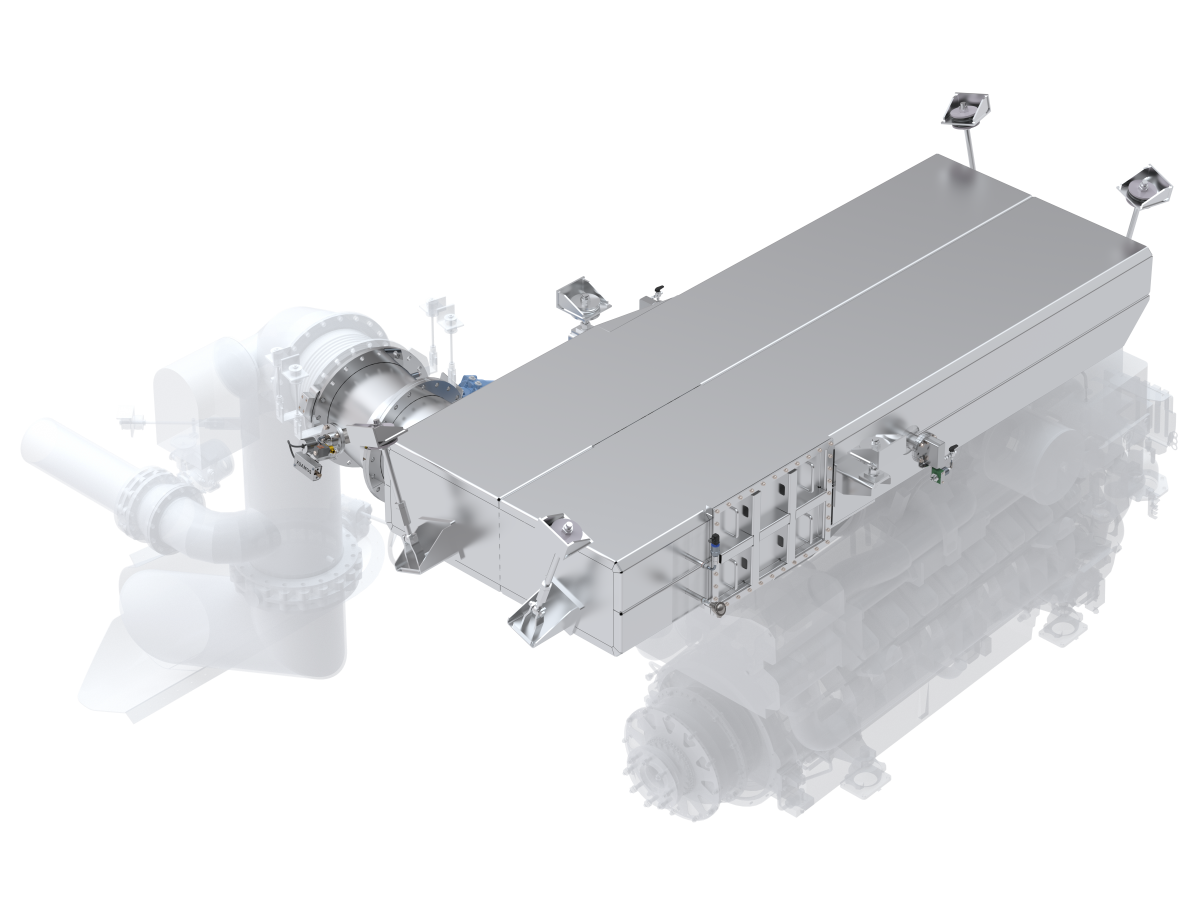

The SCR unit itself was custom built to meet the customer’s needs and engineered to be directly connected to the engine and make optimum use of the available space above the engine. A bespoke type and size of SCR catalyst was used to keep the system as compact as possible. Multiple arrangements for maximum sound attenuation were integrated within the SCR unit. The active valve to regulate the backpressure was also specifically engineered, offering a custom component that manages to be rugged while remaining compact and easy to install.

Team work

Another part of the project involved close cooperation between MarQuip and Xeamos on a high-grade stainless steel wet exhaust system which includes water injection equipment and class-approved valves.

Wet exhaust valve integration

To minimise the number of components and simplify installation and integration, the controls of the backpressure-regulating valve and wet exhaust valves were included in the Xeamos control panel. After an extensive review of documents with all parties involved, the complete functionality of the valve control as well as all safety related pre-conditions were designed and validated. Adding further value to the Xeamos system, we also supplied the local panels for monitoring and manual control of the wet exhaust valves.

Having ensured engineering and production to the highest quality standards, the installation was then supervised by Xeamos. The system has since been commissioned by a Xeamos technician and the results were spot on, precisely meeting the brief and proposed specs.