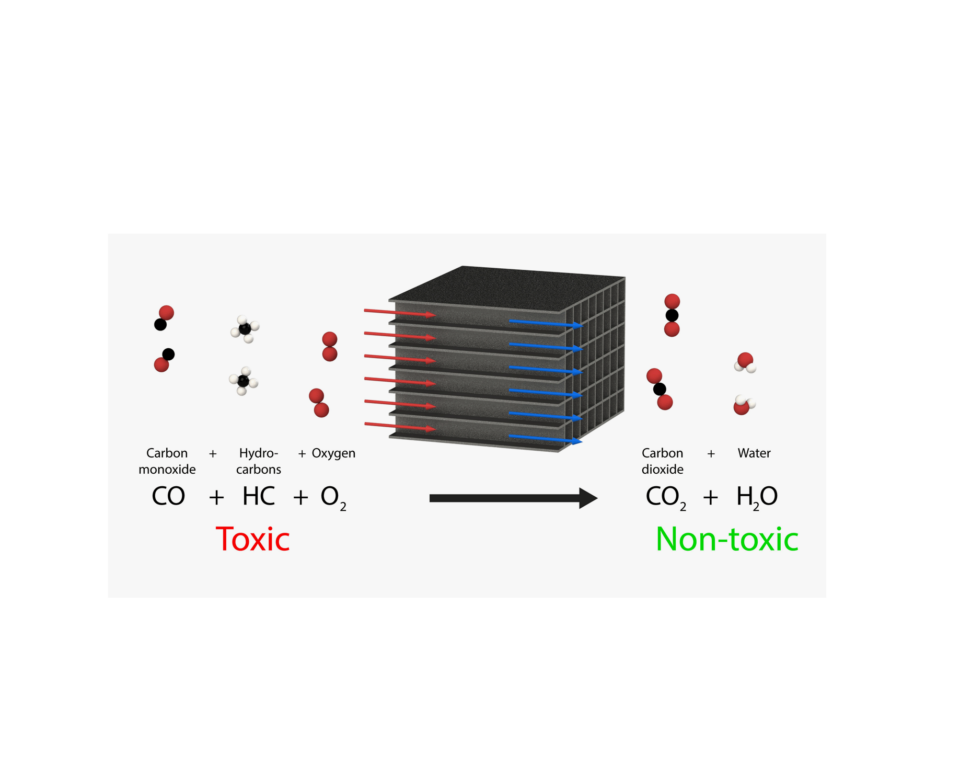

Diesel particulate filters (DPF) consist of a ceramic structure of small channels that are alternately blocked, forcing exhaust gases to flow through the thin porous walls of the filter block. Diesel particles or soot get trapped in the porous walls of the diesel particle filters. If the temperature is high enough the soot will oxidize (burn) in a process called regeneration. After oxidation a small amount of ash remains on the filter wall. The majority of the ash comes from the lubricant oil, the rest from fuel and engine wear.

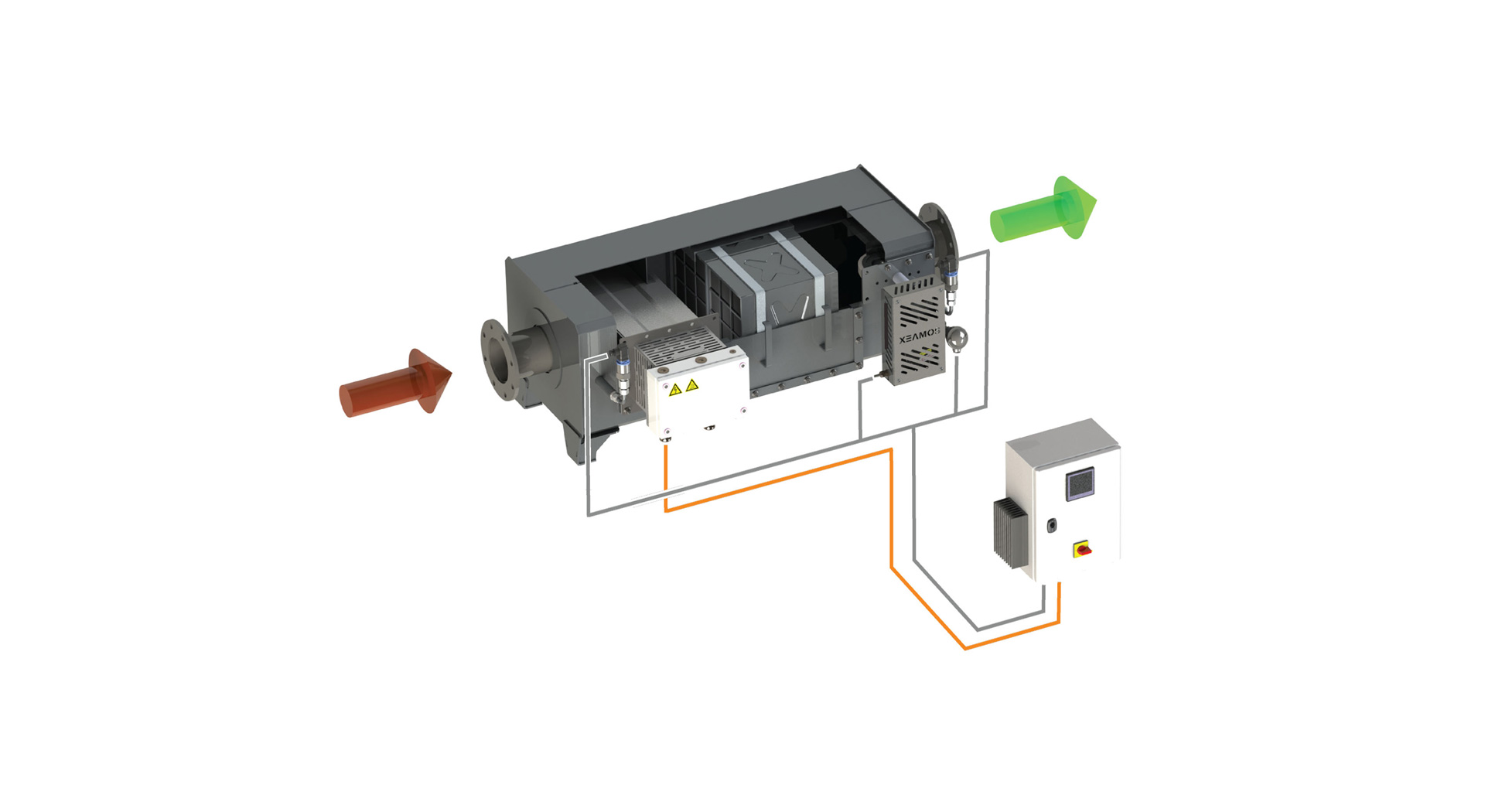

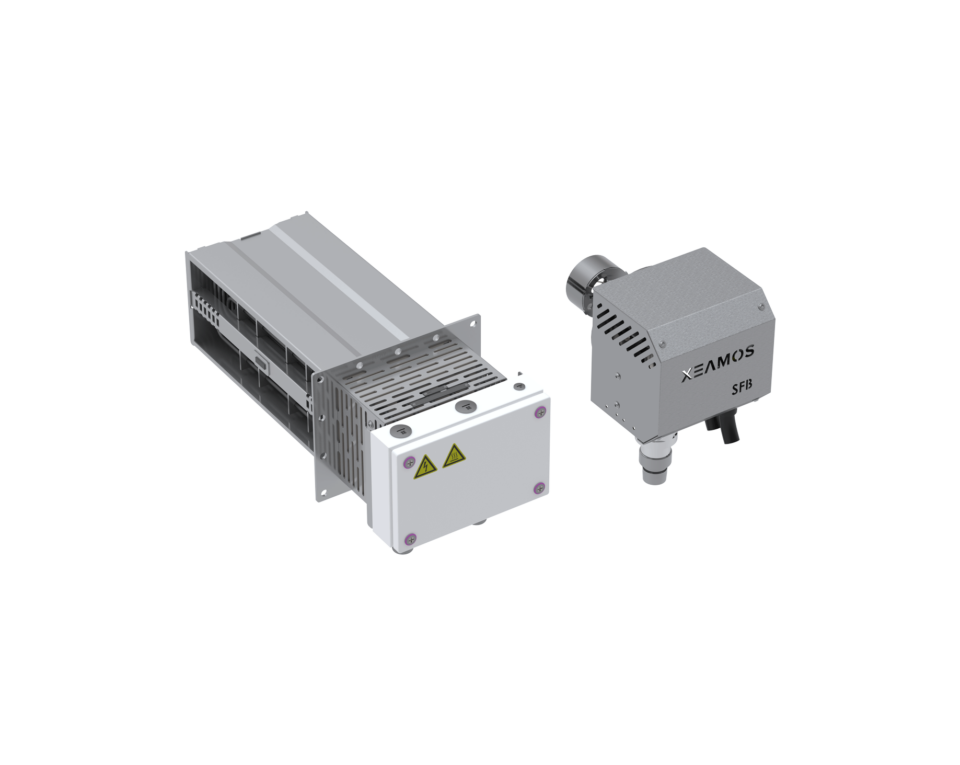

Xeamos applies robust silicon carbide diesel particle filters with a proven long-term reliability in marine applications. Our particle filters reduce more than 97% of the particulate mass (PM) emissions from the engine.