The 58-metre expedition yacht Pangaea Ocean Explorer successfully completed an extensive refit at Rivergate Marina & Shipyard in Brisbane, Australia, in February 2021. With the complete list of works including two new Zenoro 200 kW main generators as well as Xeamos IMO Tier III compliant exhaust after-treatment systems, Pangaea Ocean Explorer is leading the way in increasingly eco-friendly yachting. Here we take a look inside the refit.

Explorer yacht refit

The 58.22m Trinity Yachts designed M/Y Pangaea Ocean Explorer is a state-of-the-art deep-water marine research vessel built at Halter Marine in the United States in 1999. With the vessel arriving at Rivergate Marina in December 2020, Xeamos’ official dealer Maritime Professional Solutions (MPS) undertook an Australian-first generator installation aboard the high-tech scientific research vessel as part of a massive refit project over three months.

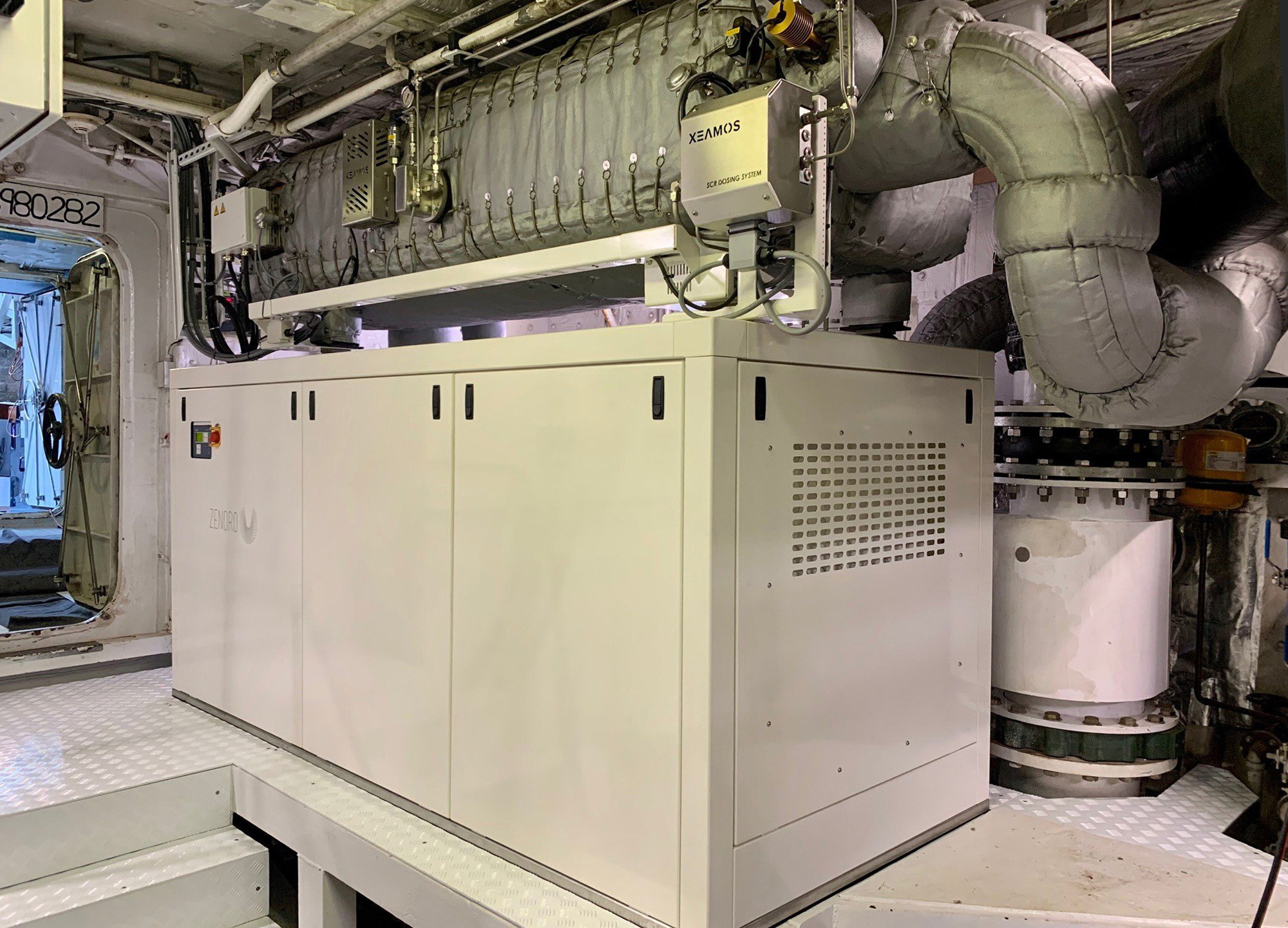

The installation involved two new Zenoro 200kW main generators and Xeamos IMO Tier III compliant exhaust after-treatment systems with DPF (Diesel Particulate Filter) and SCR (Selective Catalytic Reduction) – the very first installation of its kind in Australia.

The complex scope of works undertaken on Pangaea Ocean Explorer impacted most of the vessel’s systems, covering engineering, fabrication, painting, electronics installation and plumbing. Other works included a new 96kw emergency generator and Hamann sewage treatment plant. In addition to the new generators, Kongsberg Multibeam sonar systems were installed to allow the crew to perform hydrographic surveys in shallow waters or deep-water trenches, along with a gondola fixed in the underside of the hull which will be used in deep-sea observation and data collection.

IMO Tier III requirements

Zenoro is the world leader in custom superyacht generators. Their collaboration with Xeamos exhaust treatment systems made it the logical turnkey solution for the highest quality generator systems that meet International Maritime Organisation Tier III requirements for emissions.

“In 2016, IMO Tier III requirements came into effect,” explains Joel Allingham, MPS Director. “This means any new builds or generator refits are required to meet IMO Tier III requirements if the vessel wishes to enter any of the IMO ‘Emission Control Areas, which includes areas in the North American Pacific and Atlantic Coasts, the Caribbean and the Mediterranean. These requirements are met by installing exhaust after-treatment systems that incorporate SCR (Selective Catalytic Reduction). The Zenoro generators installed in Pangaea Ocean Explorer were equipped with Xeamos exhaust treatment systems that included SCR. The Zenoro generator systems power the entire vessel and really are the beating heart of the ship. Therefore, it is important to have the highest quality and most reliable systems in place.”

Xeamos & Zenoro: Rising to the challenge

Several challenges were impacting this ground-breaking installation, but the main issue was space in the engine room. “The owner wanted the installation to be as neat as possible while maintaining serviceability and functionality,” Allingham continues.

“With the inclusion of the Tier III exhaust treatment system, the overall unit size increases. Once assembled, the dimensions of the generators were 2850mm long x 2100mm high x 1210mm wide. “To ensure everything would fit without major modifications to the base structure and engine room layout, we made a 3D model of the engine room and the proposed installation so that the customer could see the final installation and make any required changes or requests prior to the installation commencing.”

Once the go-ahead was given, the team from MPS had to disassemble the generators into sections to allow the machinery to be installed through the aft engine room door, which was only 800mm wide. “Custom girder trolleys and a gantry system had to be designed, manufactured, and installed into the engine room to allow the machinery to be moved around the machinery space. To add to the complexity, the works were all carried out in the water, so everything was transported and lifted onto the vessel by way of barge crane.”

Eco-yachting: the Flourishing Ocean Initiative

Quiet and clean power generation is not just driven by legislation, however. Owners, yacht crew and industry, are all proving a larger and larger appetite for a cleaner and healthier environment. Pangaea Ocean Explorer and her crew are committed to finding strategies to address overfishing, the dumping of plastic, rising sea temperatures and CO2 levels, and supporting the sustainable use of ocean resources and conservation of critical habitats.

The explorer is also a pioneer of the Flourishing Ocean initiative. This initiative aims to engage the best science and latest technologies to halt damage to the ocean’s delicate ecosystems and support initiatives towards its recovery. Boasting high-tech gear, including a dive set up, underwater drones, water sampling equipment and a broadcast suite, Pangaea Ocean Explorer is undoubtedly well equipped to rise to the challenge.

To read more about the refit of Pangaea Ocean Explorer at Rivergate Marina and Shipyard in Brisbane, Australia, head to rivergate.com.au.