The latest advances in exhaust treatment systems are all very well for new-build yacht projects where they can be designed in from the start, but that’s no use if you’re one of the thousands of yachts that make up the fleet that were built before those systems were available. So want to clean up your act, but don’t know how? Clean-air specialists Xeamos have a solution for you that’s perfect for a refit or even just a retrofit project.

The problem: soot

Nothing says pristine luxury like enjoying a beautiful anchorage or harbour on a yacht – and nothing says annoyed guests and frustrated crew like those noxious exhaust fumes that can drift across the aft beach at anchor and the film of carbon that can form on the crystal clear waters around a yacht (not to mention the unsightly dark staining of the hull around the exhausts – more thankless scrubbing and polishing from the tender, anyone?).

These inconveniences are the result of particulate matter in the exhaust gases. And it’s not just about the onboard comfort and in-water enjoyment of guests, because particulate matter is particularly nasty when it comes to human health, potentially leading to cardiovascular and respiratory problems over the long term. Most yachts struggle with soot on the hull, decks and water surrounding the yacht, and the main cause is generators running at too-low loading. The ideal solution is both to increase load on the generator to optimum efficiency while also installing a soot filter – or, as it’s more technically known, a diesel particulate filter (DPF).

Example of pollution on the hull by particulate matter.

The challenge: refit

The very nature of variable generator loading presents a problem. As the loads change, so does the exhaust temperature, going from effectively ‘cold’ all the way to a temperature that is sufficient for passive regeneration in the DPF – the point at which the exhaust temperatures alone are high enough to trigger the particulate matter burn in the filter. A further complication for refit or retrofit projects is that the engine room and various systems are already set in place, meaning limited space for additional equipment. Moreover, exhaust backpressure is consumed almost entirely by the original installed exhaust system.

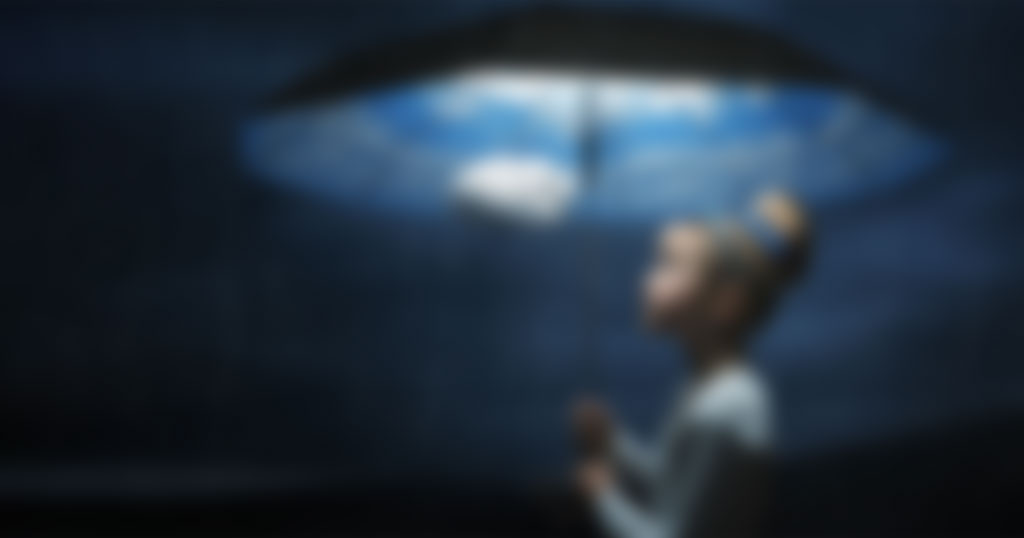

Lay-out of a Zero Soot EHS

The solution: Xeamos ZS EHS

At Xeamos, our sole focus is on creating solutions that not only help clean up exhausts as part of the original install, but which also can be fitted to yachts which are lacking suitable exhaust treatment systems. As a result, we not only created the ideal DPF solution with our ZS EHS treatment system but we also created a holistic approach for advising on which DPF installation will be best for your specific yacht refit or retrofit project.

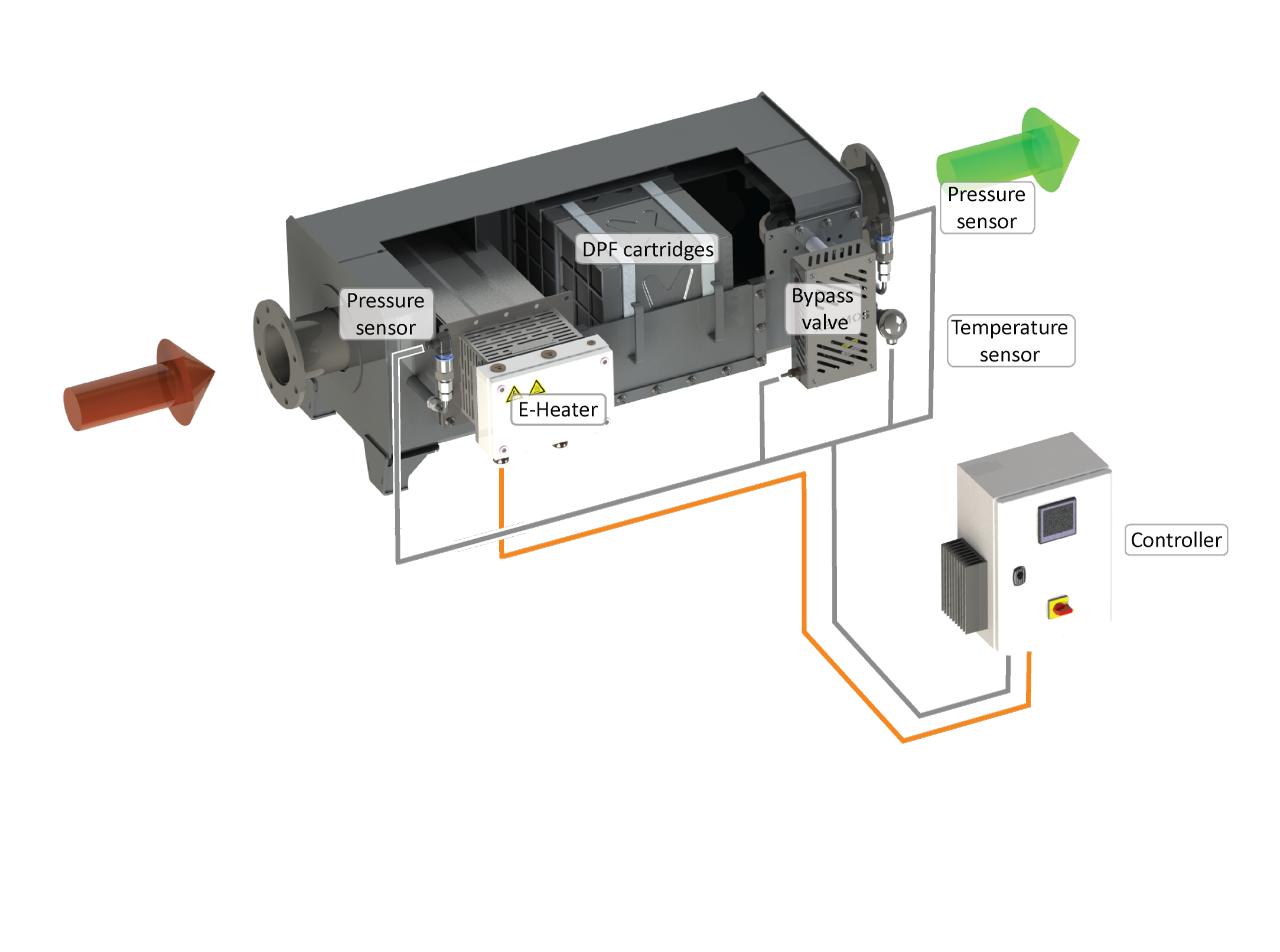

We look at all the various parameters to decide on the core components and to develop your overall solution – from engine specs and load profiles to the available space and the existing exhaust system – and then based on that analysis we will advise you on the correct custom active DPF solution for you. Our ZS EHS system (zero soot with electrical heater) offers the best of passive and active DPF systems but with ultra-advanced features that make it perfect for any yacht, and for any operating conditions that yacht may find itself in. A Xeamos ZS system will reduce soot by up to 97% at PM10 (particulate matter where the size of the measured average particles is just 10 micrometres) and will also reduce hydrocarbons in the exhaust that cause the typical, unpleasant diesel engine smell in the air.

The ZS EHS detects when load is light and exhaust temperature is low, and at that point activates the integrated heater. This offers double bonus – it means the particulate matter can be actively reduced while at the same time increasing load on the generator; when the generator reaches optimal load efficiency and the exhaust temperatures are high enough to passively reduce the particulate matter, the heater switches off. What’s more, Xeamos offers cutting edge catalytic coatings in its DPF solutions to ensure optimal particulate matter mitigation. backpressure never exceeds the set max values so you can always run your generator.

How does a Diesel Particulate Filter work?

Our ZS EHS solution features compact design, an intelligent PLC-controlled regeneration system, a range of core units tailored to generators up to an average of 250 kWm, suitability for either wet or dry exhaust configurations, and compatibility with low-sulphur content diesel. In short, Xeamos takes the challenge of fitting a DPF system to an existing yacht engine room and makes it an opportunity for you to transform your guest and crew experience safe in the knowledge your system has been custom designed by one of the world’s leading exhaust treatment engineering companies.

Example of installed DPF in existing engine room.

The Xeamos advantage

As specialists in clean air engineering, selecting Xeamos for your exhaust treatment brings huge benefits, not least of which is our unrivalled expertise in developing bespoke exhaust treatment and DPF solutions to suit any yacht project, including for refit and retrofit works.

After analysing the technical details, space, load conditions and the existing exhaust system of your yacht, we will advise on the best solution for your needs and will develop a bespoke active DPF system specific to your engine room. Our team is available to support you during the installation phase and if required we can also offer supervision during both the installation and commissioning stages for your absolute peace of mind. What’s more, our service team and worldwide dealer network allows us to maintain your new system when needed to ensure you and your guests enjoy a worry-free ‘clean air experience’ no matter where you are cruising.

Even 400 mm was sufficient height to install a DPF system.

DPF Refit

• A unique internal bypass electrical operated

allows 100% engine availability.

• In practice VIP guests will not experience the typical smell of diesel exhaust, grease and soot particulates on deck and in the swimming water.

• Our system range has been designed especially to form a perfect match with generators up to 250 kWm engine power, for either dry or wet exhaust configurations. The Electrical Zero Soot System allows diesel with up to 1000 ppm sulphur content.

• The intelligent PLC controlled regeneration

system ensures a trouble-free operation of

your filter system.

• The electrical heater element allows integrated load bank functionality, and keeps your engine performance better by utilizing higher loads.

Get in touch

Everyone wants a happier, cleaner and healthier environment on their yacht, so contact us today to discuss your project and to find out how we will develop your custom refit solution.