Emissions control is becoming ever more prevalent and even tighter, and it’s not just about exhaust gases. Potentially harmful exhaust particulates also need to be mitigated in order to clean up the environment. But for yachts there is another consideration: when enjoying the most beautiful spots the coasts and oceans have to offer, no one wants to suffer the unmistakable smell of an exhaust, nor do they want to swim in water carrying a fine carbon coating on its surface. Enter Xeamos’s ZS-EHS diesel particulate filter (DPF) system.

What is the ZS-EHS?

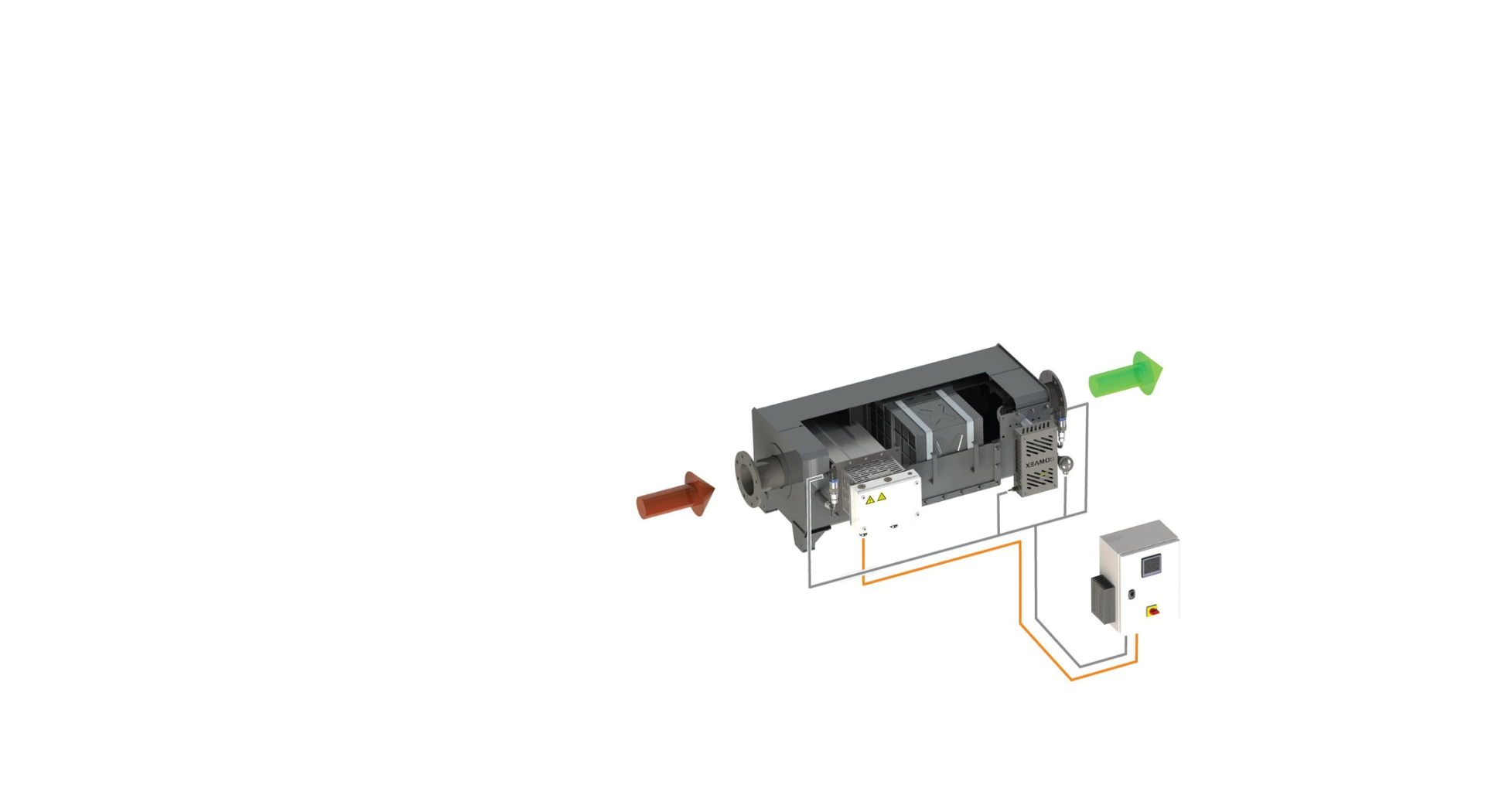

ZS-EHS stands for Zero Soot Electrical Heater System. This system consists of a Diesel Particulate Filter (DPF) and an electrical heater that has been designed by Xeamos. The DPF collects soot and ash from the engine and, along with the E-heater, burns off the soot particles through processes called passive and active regeneration (for more on the working principles of the DPF and regeneration, explore the Xeamos whitepaper How does a diesel particulate filter work?).

Benefits of the ZS-EHS

The comfort of a yacht is absolutely essential to ensure the satisfaction of the customer, be they an owner, guest or charterer. The ZS-EHS systems captures the soot and ash that is produced in the engine, and treats it before it can be released to the atmosphere. The result is clear – the hull and deck remain free of black particles and thus clean, and the telltale odour that soot creates is mitigated, improving the experience for guests and crew on board.

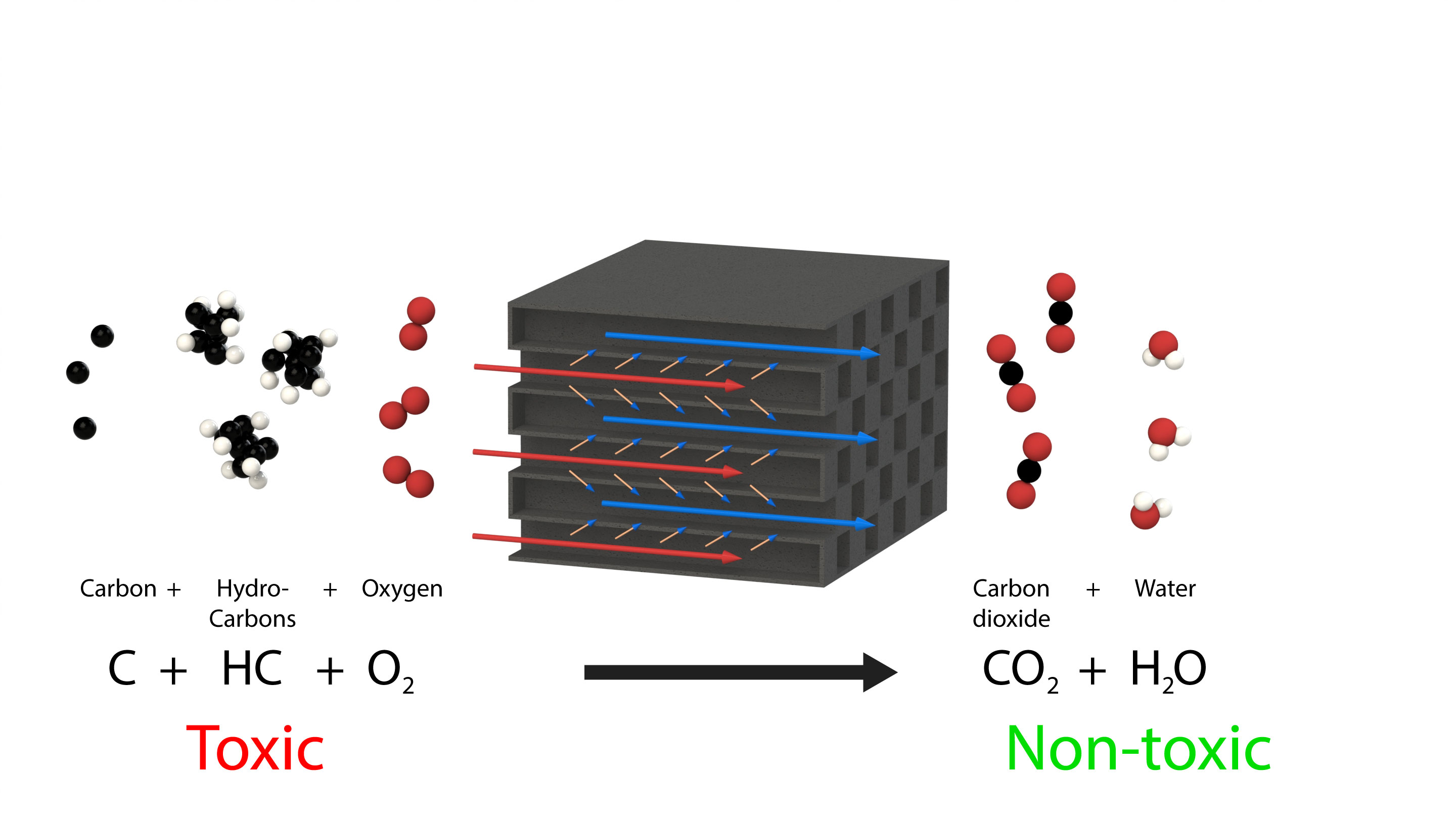

There’s a more fundamental reason why such treatment is important, however. Untreated exhaust fumes contain soot, also known as particulates, and these can be breathed in, penetrating the lungs. Further, the smaller particulates can be absorbed into the bloodstream, posing a considerable health hazard that can lead to cardiovascular and respiratory problems over the long term. Such particulates – comprising carbon, hydrocarbons and ash residue – are defined as PM10 or PM2.5, which means the size of the measured average particles is just 10 micrometres or 2.5 micrometres respectively (read more about particulate matter in the Xeamos whitepaper here).

The DPF systems developed by Xeamos reduce the particulate matter by 99.9%. What’s more, that typical diesel odour around the yacht is caused by unburned hydrocarbons – the ZS-EHS, and other DPF systems of Xeamos, convert these hydrocarbons and in doing so remove the diesel odour. With a special Bay mode functionality, the system is even in operation at very low engine loads. This makes sure that the water around the vessel remains clean for swimming and other water activities.

Safety and reliability are of major importance on ships. Engine power must be available anytime, everywhere, and therefore the back-pressure in the system must not exceed the engine limits. An integrated bypass ensures that the backpressure of the engine remains within limits and thereby ensures availability of the engine. The bypass operates on a simple principle: when the backpressure becomes too high, the bypass opens thus releasing the pressure with the result that the backpressure drops instantly. The opening of the bypass is controlled to maximize the soot filtration while maintaining an acceptable backpressure. The system is extremely reliable and provides continuous operation.

All Xeamos products are set by parameters. This means that Xeamos systems are highly flexible, and our expert team are determined to fit a system that slots perfectly into your specific application. Besides soot capturing, and CO and HC reduction, all Xeamos systems also function as a muffler and in most cases the sound attenuation of the Xeamos system is actually higher than that of a muffler.

The ZS-EHS systems are made of high-quality stainless steel. This makes them resistant against high temperatures and corrosion, ensuring longevity and ease of maintenance.

Integration in the PMS

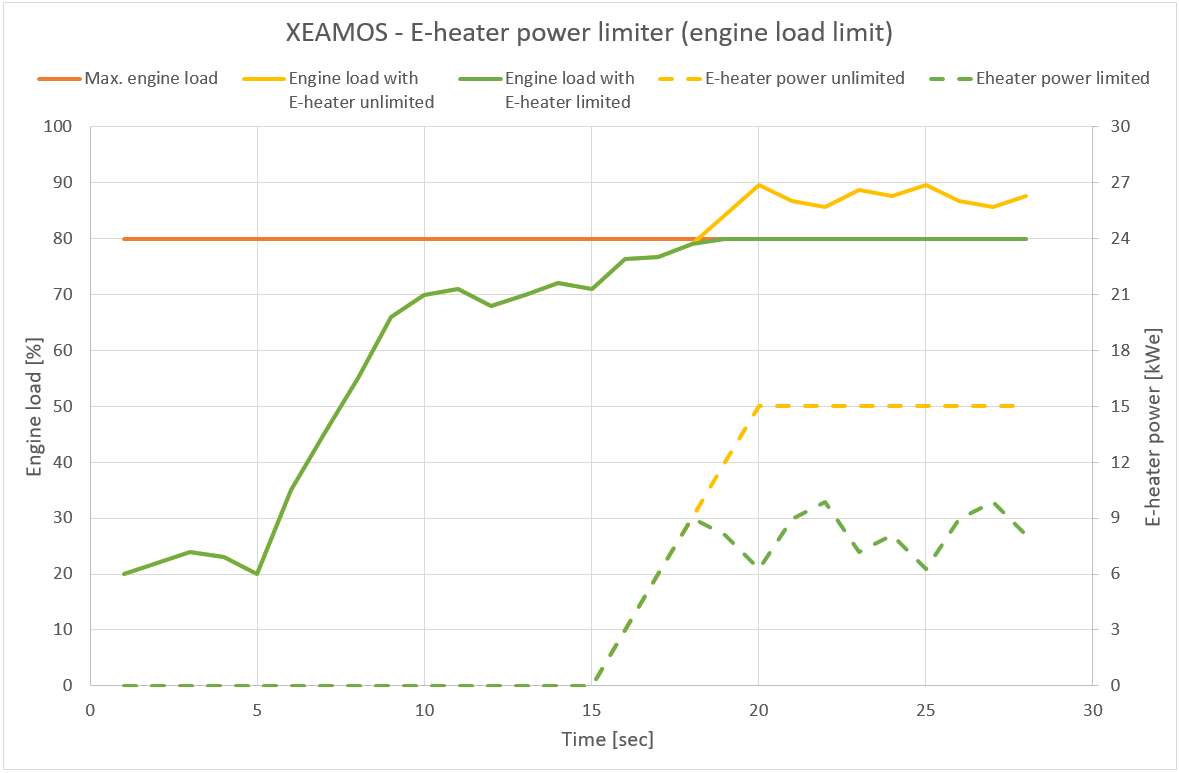

The Xeamos E-heater has been engineered in-house by our expert team, and it connects seamlessly into the grid. The power required by the E-heater depends on a number of factors, including the exhaust flow, temperature, and the DPF coating used. This power is controlled automatically, which conveys several advantages – for example, smooth power control prevents voltage drops for continuous power availability. The power-limiter feature limits the heater power at high generator loads preventing an overload and/or the starting of another generator to meet the power demand. In the case of multiple ZS-EHS systems being installed, regenerations can be performed sequentially so that peaks of power demand are minimized.

Another feature is the ‘heater-allow’ function. This function enables the PMS to delay the active regeneration to a moment where the hotel load is relatively low, for example at quiet moments during the day or at night.

Advantages of the E-heater

When applying this system for a generator, the effect of the E-heater on the exhaust temperature delivers a double hit: first, the E-heater increases the temperature of the exhaust and pushes it into the regeneration zone; and then second, the power demand of the E-heater increases the load on the generator which in turn also increases the exhaust temperature. This makes the E-heater very efficient and very effective.

Coatings

The particulate filters of all ZS-EHS systems have a coating which functions as a catalyst that enhances the oxidation of soot. The most common coatings of this system are SX and ZX, which are the most active coatings which in turn means the regeneration temperature can be minimized. This decreases the power required for regeneration. The most suitable coating is case-dependent and, among other things, is affected by the fuel being used – for instance, the amount of sulphur in the fuel has an impact on the coating that can be applied.

One of the big advantages of very active coatings is passive regeneration, where the coatings decrease the temperature needed for regeneration such that when the engine is running at a higher load, the temperature of the exhaust is sufficient to regenerate the filter without using the E-heater to bring the temperature up (which is called active regeneration). This means the E-heater can remain off, which improves the energy efficiency of the system.

Maintenance

As soot and ash from the engine accumulates in the DPF over time, this can lead to an increase in the backpressure, so to protect the engine from high backpressures the system starts regeneration automatically. The total regeneration process takes less than one hour. The regeneration interval is mainly determined by the engine emissions, fuel used, engine wear, and oil consumption. Indeed, proper engine maintenance is beneficial for the after-treatment system.

The soot the DPF collects is mainly carbon, while the ash mainly comprises metals. During regeneration, the soot is oxidized and becomes carbon dioxide and water, leaving the system with the exhaust gases. The ash remains in the DPF, and therefore the DPF must be cleaned periodically. This cleaning is undertaken by a qualified cleaning partner, and comprises an automated process using pressurized air and a heating cycle during which residual oil deposits are burned off. Proper maintenance of the engine and the type of lubricating oil used impacts ash production considerably, as the two main sources and causes of ash are the lubrication oil and engine wear. The result is that proper engine maintenance can extend the cleaning interval of the Xeamos system, in other words decreasing the frequency of filter maintenance.