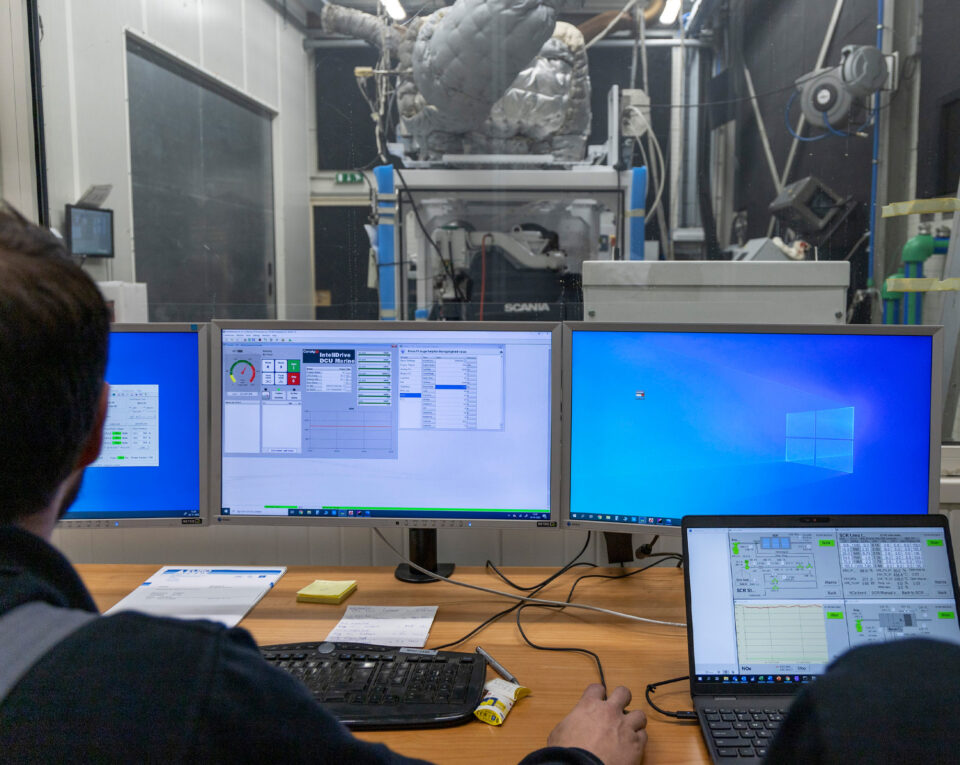

All our systems are developed and tested in-house

Xeamos is an engineering firm and all our systems are developed and tested in-house. We also offer expertise in areas such as sound attenuation and soot filter and SCR technology, combining everything within a single system. Models that have not been used before are meticulously checked by our engineers using dedicated software to ensure they function optimally. If required, we can calculate the pressure drop of the entire exhaust system, and make thermal and/or power calculations. We are fully up to speed with the latest regulations related to emissions, safety and more, and can provide you with a system that offers a guaranteed performance and lifespan.

Our USP's

• Standard and customised solutions for emission reduction

• IMO Tier III compliant

• Robust systems in a steel type of the customer's choice

• Flexible partner for yacht builders and shipyards

• Specific preferences can be integrated quickly

Compliance with IMO

Tier III regulations

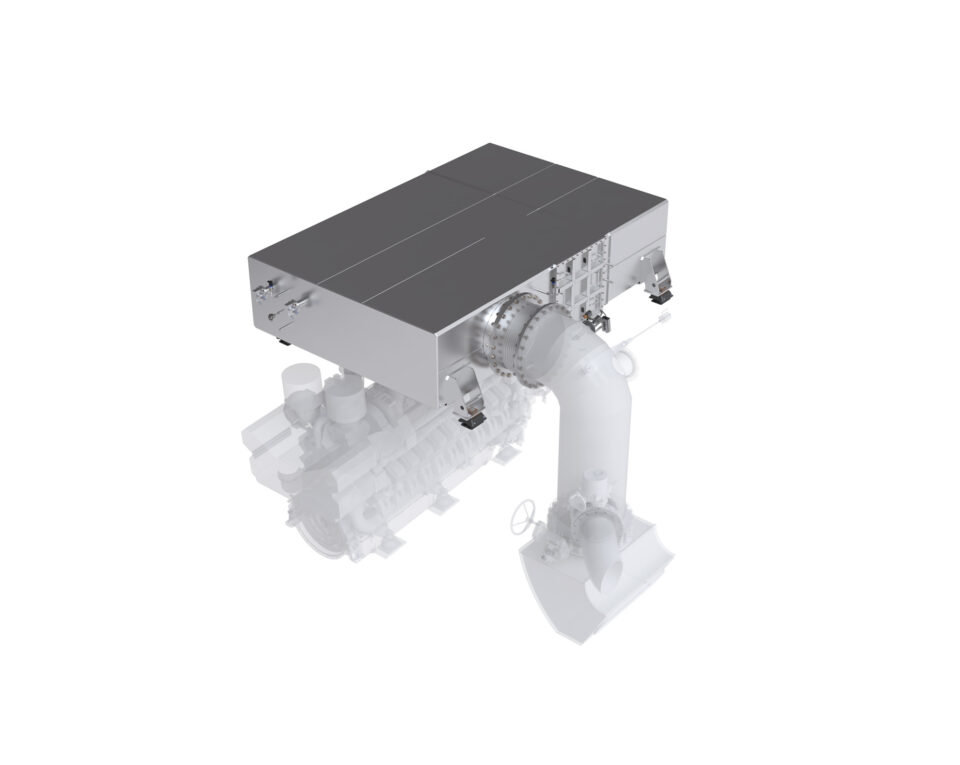

The new International Maritime Organization regulations include strict requirements for nitrogen emissions. In so-called Emission Control Areas, such as the coastal regions of North America and the Caribbean, IMO applies Tier III: an emission standard of less than 2 g/kWh, depending on the nominal rpm. This means that all engines with a capacity of over 130 kilowatts, on yachts of more than 500 GT, must be fitted with an SCR catalyst. To meet these requirements Xeamos can provide you with robust systems designed for a long lifespan.

Low TCO

The Xeamos systems have a reputation in the market for their sound and robust design and long service life. As a shipping entrepreneur, this means that you benefit from low maintenance costs and a low Total Cost of Ownership (TCO), as well as benefiting from the design choices we have made.

Flexibility

Xeamos may not be the largest supplier of systems for the yachtbuilding sector but we are almost certainly the most flexible. Where required we can provide integrated solutions for a soot filter system and SCR catalyst, or integrate a silencer in the SCR system. Sizes and connections are aligned to the onboard engine, and we also provide custom controls, with features such as connections to a wide range of monitoring systems. Both can be used on new builds and refits alike and the fact that we always provide custom solutions makes us the ideal partner for all projects.

Customisation

Xeamos systems are unique because of their specific alignment to the application. They are specifically designed to match the type of engine, load profile of the engine, fuel type, installation space and any specific user demands. This explains why we provide such a wide diversity of systems, instead of a single standard system for multiple applications. Dutch design and Dutch in-house engineering at its best.

The components we use are of industrial quality and have the look and feel superyacht yards and owners expect. While Xeamos won’t be the cheapest option, you will always earn back your investment in the long term due to the low operational and replacement costs.

Technologies

CASES

Our latest yachting cases

-

Cases: Super explorer refit: inside the 58m Pangaea Ocean Explorer

The 58-metre expedition yacht Pangaea Ocean Explorer successfully completed an extensive refit at Rivergate Marina & Shipyard in Brisbane,... -

White Paper: How does a diesel oxidation catalyst work?

A diesel oxidation catalyst (DOC) is manufactured from very thin corrugated layers of stainless steel with a very thin layer of particles... -

White Paper: Modular airless Zero NOx IMO Tier III SCR system

For those not in the know, a SCR system is used in diesel engines such as those found in maritime vessels to transform exhaust gases such...