Customisation

In May 2022, the Dutch government announced that the ‘particulate matter’ (or ‘DPF’ part of emissions after treatment) would form an important part of the allowance regarding compensation for STAGE-V-related investments, which are currently under consideration by parliament. That means that ‘DPF’ can also be considered to be part of your financial allowance, alongside the existing NOx-related financial allowance. Xeamos is proud to offer our customers the opportunity to handle the entire STAGE-V administrational procedure for you, encompassing all of the ins and outs of the allowance appeal. In this way, we save you from needing to take part in this frequently time-consuming administrative procedure – and that’s one less thing for you to worry about.

Engineering

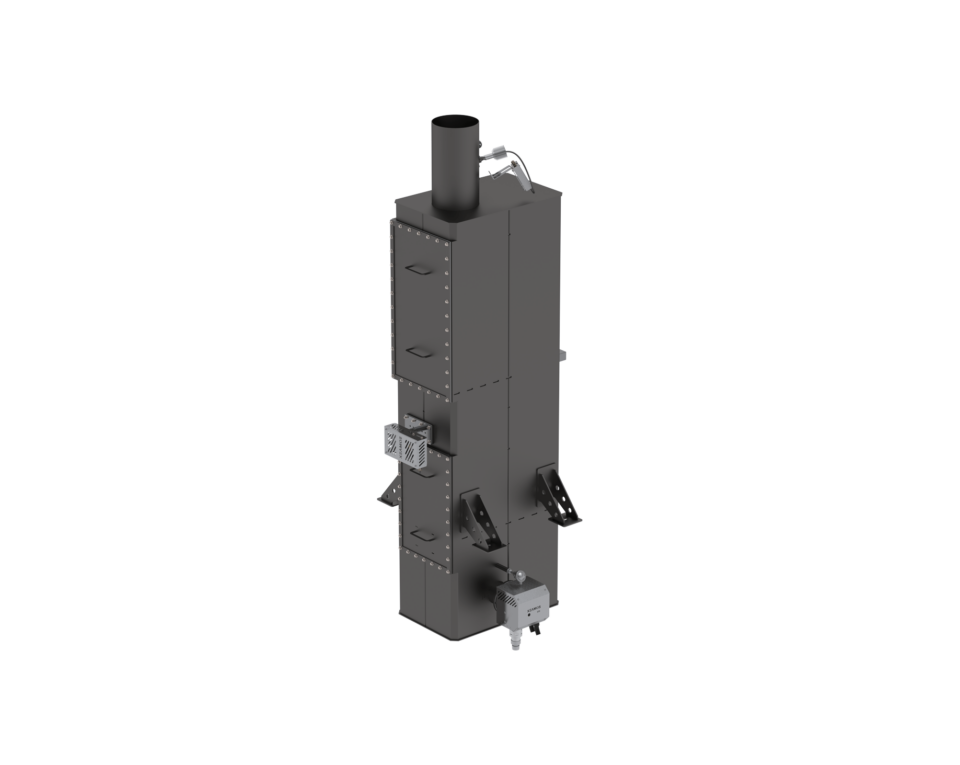

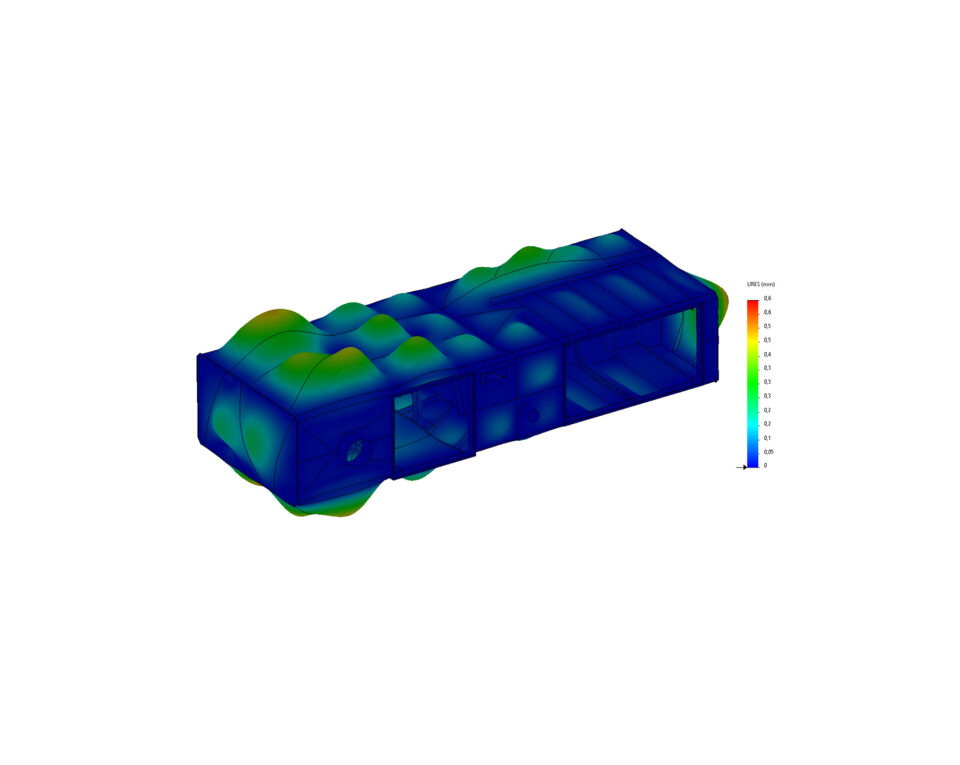

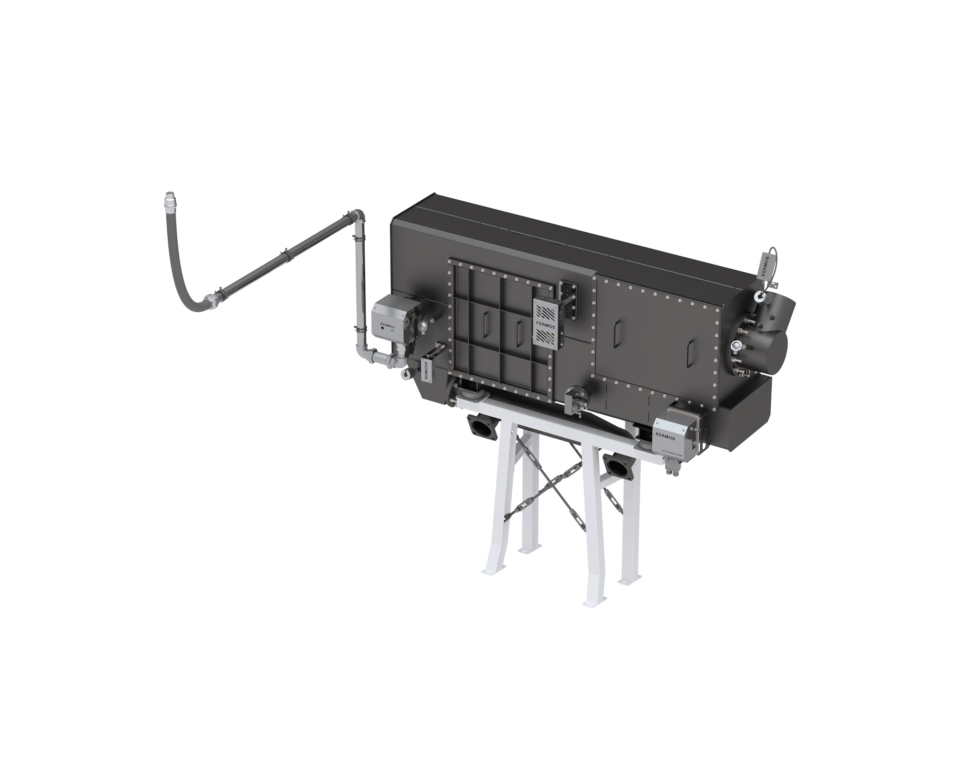

Xeamos is an engineering firm and all our systems are developed and tested in-house. We also offer expertise in areas such as sound attenuation and soot filter and SCR technology, combining everything within a single system. Models that have not been used before are meticulously checked by our engineers using dedicated software to ensure they function optimally. If required, we can calculate the pressure drop of the entire exhaust system, and make thermal and/or power calculations. We are fully up to speed with the latest regulations related to emissions, safety and more, and can provide you with a system that offers a guaranteed performance and lifespan.

Installation and check

We believe that it is important that our systems are integrated correctly. We therefore always ensure that the shipyard or yard has all the documentation required in advance. We will also check the installation work on site. Furthermore, during commissioning, we will perform different tests using professional measuring equipment. As a result, you will be able to prove that you meet all emission standards - not only on paper but also in practice.

Our USP's

• Standard and customised solutions for emission reduction

• Precisely calculated and then tested in practice

• Robust construction and long service life

• Lower maintenance costs and a lower TCO

Low TCO

The Xeamos systems have a reputation in the market for their sound and robust design and long service life. As a shipping entrepreneur, this means that you benefit from low maintenance costs and a low Total Cost of Ownership (TCO), as well as benefiting from the design choices we have made.

Technologies

Cases

Our latest inland navigation cases

-

Cases: Meeting the strictest future emission standards: MVS Zembla

The 135-metre MVS Zembla was built by shipyard Gebroeders Van de Wijgaart. With a beam of 17 metres, this impressive inland vessel has two... -

White Paper: How does a diesel oxidation catalyst work?

A diesel oxidation catalyst (DOC) is manufactured from very thin corrugated layers of stainless steel with a very thin layer of particles... -

White Paper: Diesel particulate filter or catalytic converter system?

Although most systems that can be obtained on the market operate based on the same operational principles, there are significant...